Automatic High-Speed UV Coating Machine Series

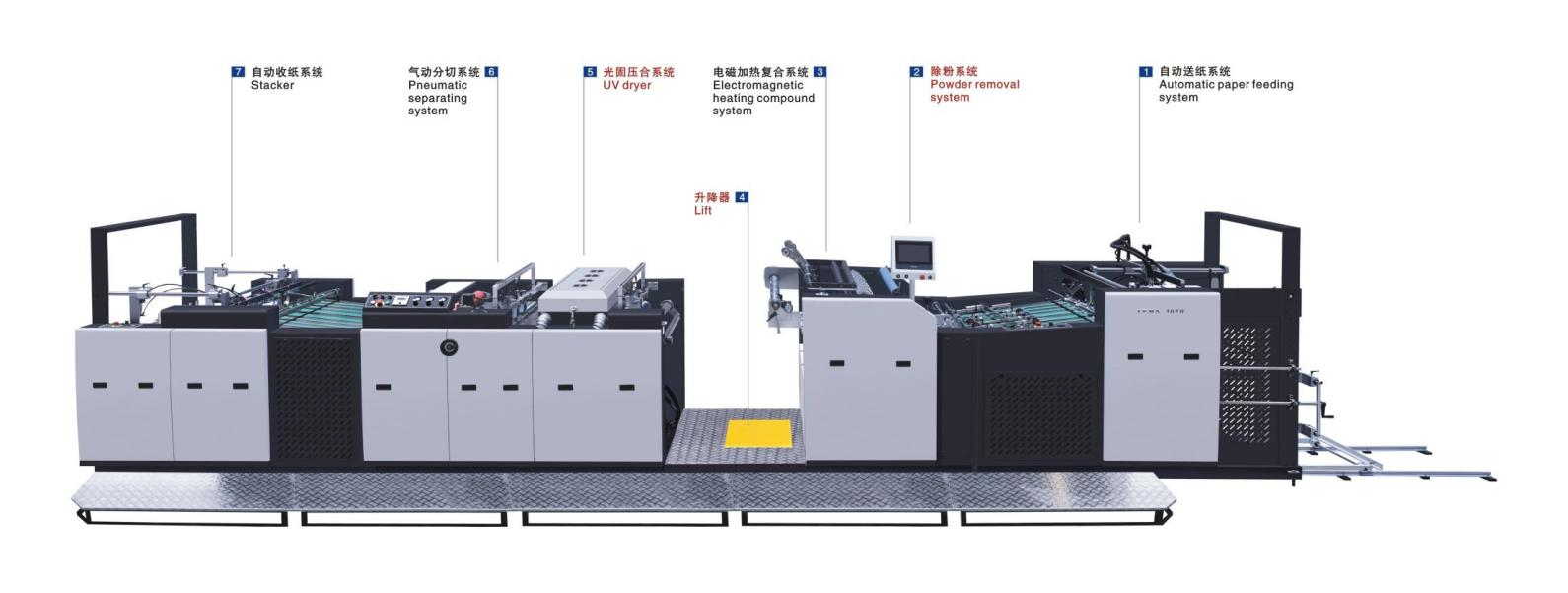

Fully Automatic UV Curing Standard Model

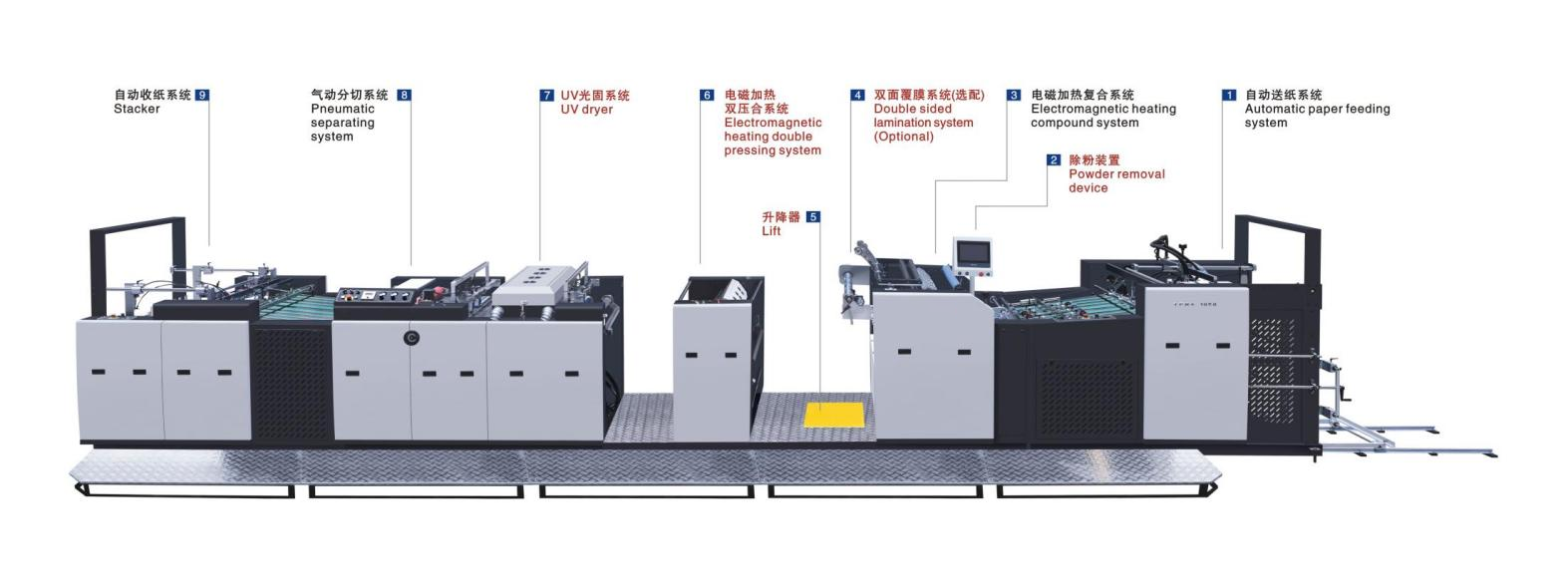

Dual-Pressure + UV Curing Type (Optional)

UV Curing + Chain Knife (Optional)

Dual-Pressure + UV Curing + Embossing Type (Optional)

Technical Parameter

Item | YFMD-850A | YFMD-1050A | YFMD-1200A |

Max laminating paper | 850*1050mm | 1050*1050mm | 1200*1050/1450mm |

Min laminating paper | 290*290mm | 300*300mm | 420*420mm |

Paper weight | 80-500g/㎡ | 80-500g/㎡ | 80-500g/㎡ |

Interface tolerance | +_2mm | +_2mm | +_2mm |

Laminating speed (depend on paper quality,color and color area) | Single side: 0~100m/min Double side: 0~60m/min(optional) | Single side: 0~100m/min Double side: 0~60m/min(optional) | Single side: 0~100m/min Double side: 0~60m/min(optional) |

Power | 35kw | 38kw | 38kw |

Working power | 18KW | 20KW | 20KW |

Paper feed height | 1150mm | 1150mm | 1150mm |

Paper stack height(including plate) | 1050mm | 1050mm | 1050mm |

Overall Dimensions | 8600*1800*2000mm | 8600*2000*2000mm | 8600*2000*2000mm |

Toatl weight | 7500kg | 8000kg | 8000kg |

Detailed Function Configuration Introduction

The paper feeder is an important component of the laminating machine. The function of the paper feeder is to automatically, accurately, smoothly, and periodically separate the paper sheets one by one and continuously feed them to the designated positioning components.

The paper feeding method of this machine is continuous feeding, which has the advantages of high automation, compact structure, good performance, convenient operation, accurate paper feeding, and high precision. The main components of the paper feeder include the paper feeding bridge, the paper feeding head, the paper stacking table, the lifting system, and the transmission system.

(1) Adopting an oil-free vacuum air pump paper suction system;

(2) High speed offset printing Feida (12000 sheets/hour) ensures high-speed and stable operation!

(3) Stepless frequency conversion speed regulation for paper feeding

(4) The vacuum suction positioning conveying on the paper feeding table of the production line ensures smooth, neat and stable conveying.

(5) The upper and lower limit protection devices of the paper feeding table; Manual quick lifting and lowering;

(6) Automatic paper supply system for paper feeder;

(7) Attached dual sheet controller: dual or multi sheet feed detection shutdown system: using the induction of a safety voltage detector to detect dual or multiple sheets of paper;

(8) Centralized control of servo technology, PLC control, and human-machine interaction system, with a printing paper stacking error of ± 2mm;

(9) Front lay/pull lay positioning system

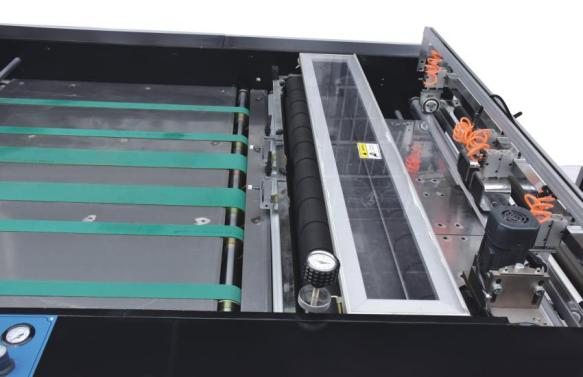

- Film lamination main machine and its advantage:

(1) The whole machine adopts high-precision synchronous belt and some imported chain drives;

(2) 320mm composite heating roller, matched with electromagnetic variable power heating system;

(3) 300mm imported silicone pressure roller, with good temperature resistance, pressure resistance and non stick performance;

(4) Electromagnetic heating

(5) Bending roller guide film

(6) Temperature measurement

(7) Automatic hydraulic

(8) Paper shortage, paper breakage, shutdown protection

(9) The powder removal for better surface effect

(10) Anti debris magnet safety device, protecting iron rollers!

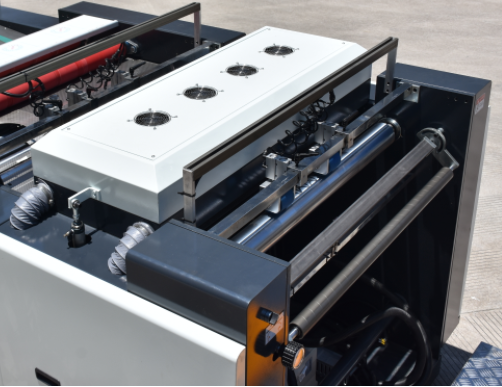

- Slitting system

(1) Rear punching

(2) High speed disc cutter

(3) Anti curling device flattens paper

(4) Pneumatic bouncing slitting

(5) Slotting of slitting rubber rollers

(6) Adopting a centralized control system for the entire machine, achieving precise pneumatic breaking

- UV photobonding system and its advantages

(1)sucking and exhaust device system

(2) The UV part adopts an 8-12KW adjustable electronic light source, which improves safety performance compared to traditional transformer light sources. It can also adjust brightness automatically according to the speed of machine operation, and can save more than 30% of average energy consumption from 30% to 100% variation.

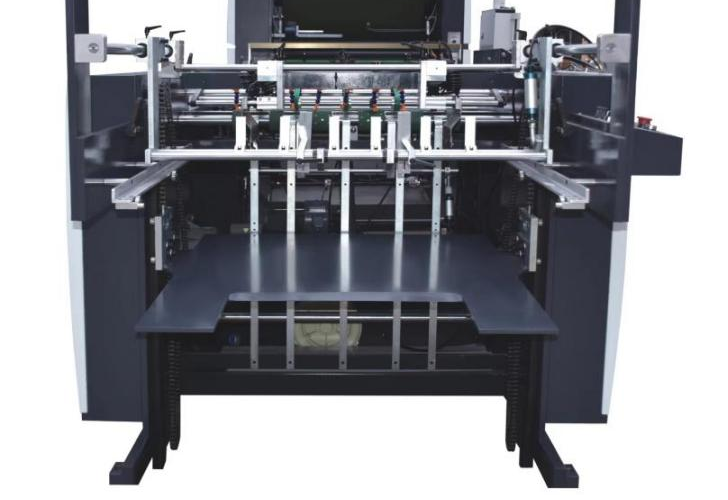

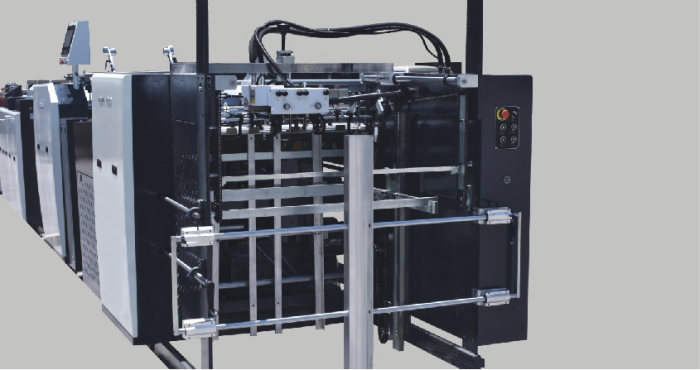

- automatic paperstackerand its advantages

The automatic paper delivery machine is equipped with a fan cooling and pressing structure, which can perfectly collect paper under high-speed operation, ensuring that the paper is received neatly.

The automatic paper receiving machine advantages as below:

(1) Thin paper tile receiving system, vacuum suction paper stabilizer device, to keep the paper stable;

(2) Manual and fast lifting of the paper receiving table;

(3) On the paper receiving table Lower limit protection device;

(4) Automatic descent device for paper receiving table, and limit stop and alarm system for paper receiving;

(5) Automatic paper accumulation counting;

(6) Matching paper blockage detection system to achieve intelligent deceleration

(7) Adopting a high-speed pneumatic photoelectric single sheet paper shooting system, the paper shooting is accurate and neat;